Product | 19 Dec 2024

Construction, agriculture, and industrial operations are some of the most demanding industries at present. Hydraulic systems are called the lifeblood of industries as they keep the machinery running efficiently for these industries. From excavators and tractors to manufacturing equipment, all these systems heavily rely on clean, contaminant-free hydraulic fluid to function properly. As advancements in technology take place and equipment becomes better but more complex, the need for advanced hydraulic filtration has never been greater. Next-generation hydraulic filters are all set and rising to meet this challenge, offering improved performance, longer service life, and enhanced protection for your valuable machinery. Let’s understand how:

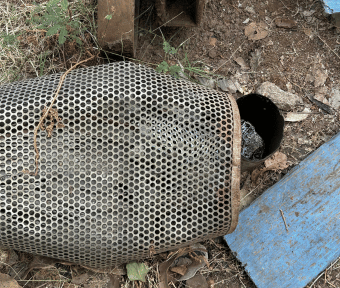

The Critical Role of Hydraulic Filtration

Before delving into the latest innovations, it's important to understand why hydraulic filtration is so crucial. Studies have shown that up to 75% of all mechanical failures in hydraulic systems can be traced back to contamination issues. Even microscopic particles can cause significant damage over time, leading to premature wear, reduced efficiency, and costly downtime.

Hydraulic filters serve as the first line of defense against these contaminants, removing particles, water, and other impurities from the fluid. By maintaining clean hydraulic oil, filters help:

- Extend the life of components like pumps, valves, and actuators

- Improve overall system efficiency

- Reduce maintenance costs and unplanned downtime

- Enhance equipment performance and reliability

Advancements in Filter Media Technology

One of the most significant developments in next-generation hydraulic filters is the evolution of filter media. Traditional cellulose media is being supplemented or replaced by advanced synthetic materials that offer superior filtration capabilities:

- High-performance synthetic media: These materials can achieve absolute filtration ratings for particles as small as 3 microns, providing exceptional protection for sensitive components.

- Multi-layer designs: By combining different media types, manufacturers can create filters that offer both high dirt-holding capacity and fine particle capture.

- Nanofiber technology: Ultra-fine fibers can be incorporated into filter media to enhance particle retention while maintaining low-pressure drop.

Improved Filter Designs for Real-World Conditions

Next-gen filters are designed to perform better under the challenging conditions faced in construction, agriculture, and industrial applications:

- Dynamic flow performance: New testing standards like ISO 23369 evaluate filter efficiency under fluctuating flow rates, more accurately simulating real-world conditions. This has led to filter designs that maintain high efficiency even during rapid changes in hydraulic system demand.

- Enhanced dirt-holding capacity: Innovative pleat designs and optimized media configurations allow filters to trap more contaminants before requiring replacement, extending service intervals.

- Pressure-resistant construction: High-pressure filters capable of withstanding up to 280 bar are now available, meeting the demands of increasingly powerful hydraulic systems.

Smart Filtration and Condition Monitoring

The integration of sensors and connectivity features is bringing hydraulic filtration into the digital age:

- Real-time contamination monitoring: Sensors can detect changes in fluid cleanliness, allowing for proactive maintenance before issues arise.

- Predictive maintenance: By analyzing filter performance data over time, operators can optimize change intervals and reduce unnecessary filter replacements.

- Remote monitoring capabilities: Cloud-connected systems enable off-site tracking of filter status across entire fleets or facilities.

Application-Specific Innovations

Recognizing that different industries have unique filtration needs, manufacturers are developing specialized solutions:

- Construction: Filters designed to handle high levels of abrasive particles encountered on job sites.

- Agriculture: Solutions that can cope with varying temperatures and exposure to organic contaminants.

- Industrial: High-flow capacity filters for large-scale manufacturing and processing equipment.

Installation and Maintenance Considerations

To fully benefit from next-gen hydraulic filters, proper installation and maintenance are essential:

- Ensure compatibility: Always use filters that meet or exceed OEM specifications for your equipment.

- Follow recommended change intervals: Even advanced filters have limits – adhere to manufacturer guidelines or condition-based recommendations.

- Practice contamination control: Use clean practices when servicing hydraulic systems to prevent introducing new contaminants.

Conclusion

There are a lot of new age advancements in hydraulic filtration technology that offer significant benefits for operations for industries like construction, agriculture, and industrial etc. By investing in next-generation filters, you can protect your equipment and improve efficiency, while also reducing hefty downtime. As this industry continues to evolve, staying updated about the best available filtration solutions is crucial for maintaining a competitive edge.

If you are looking for cutting-edge hydraulic filtration solutions, Fleetguard Filters Private Limited offers a complete range of products created to meet the demands of modern equipment. With 37 years of extensive experience and a commitment to innovation, we provide best in class filters that include the advanced technologies discussed in this article. Designed for specific industry applications, Fleetguard's hydraulic filtration systems are engineered to keep your operations running smoothly and efficiently. To learn more about how our next-generation hydraulic filters can benefit your business, visit www.fleetguard-filtrum.com and get in touch with us.